Order the Finest Durable Alloy Steels

Fast Global Shipping Prompt Local Delivery

-

Maintenance Alloy Steels

Maintenance Alloy Steels

-

Stainless Steel Alloys

Stainless Steel Alloys

-

Abrasion & Impact Resistant

Abrasion & Impact Resistant

- High tensile strength alloys

- Chromium carbide overlay

- UHMW plastic

-

Tool & Die Steels

Tool & Die Steels

-

Standard AISI Alloys

Standard AISI Alloys

-

Complete Ameralloy Catalog

Complete Ameralloy Catalog

When it comes to high-quality alloy steel products, Ameralloy Steel Corporation is a leader in the industry. With over 40 years of experience, we have developed trademark specialty grades of heat-treated steels and other materials for industries such as automotive, defense, mining, power generation, agriculture, oil and gas, transportation, and many more industries.

Our unique technical knowledge allows us to help customers find solutions for their specific applications that are difficult or impossible to find elsewhere. Our broad selection of specialized steel alloys, including tempered ultra-high-strength steels, provide superior wear resistance with excellent corrosion properties. Ask about our trademark material Durelloy and Amara-braze.

With our commitment to quality assurance through ISO 9001 registration, we’re confident that you can trust our processes no matter how complex your project may be.

Advantages of using alloy steel in industrial projects

Alloy steels are the perfect material for industrial projects, offering many advantages. Here are

five of the top benefits that they provide:

- Durability: These steels are incredibly durable, making them the perfect choice for projects that require materials to withstand harsh conditions or regular wear and tear. They are also corrosion-resistant, making them an ideal material for outdoor applications.

- Cost-Effective: These steels are relatively inexpensive compared to other types of steel and offer superior performance in terms of strength and durability. This makes alloy steel a cost-effective solution for industrial projects.

- Machinability: These steels can be used in various forms, from flat sheets to complex shapes and components. As such, they are often the preferred material for custom industrial projects that require precision fabrication and machining services like welding and cutting.

- Strength: These steels are solid and sturdy, perfect for projects requiring materials to withstand heavy loads. They also offer excellent tensile strength and can be manipulated into complex shapes to meet specific requirements.

- Customization: Thanks to their versatility, alloy steels can easily be customized according to the project’s needs. Depending on the project requirement, they can be heat-treated or cold-worked to achieve different levels of hardness or strength. This allows industrial projects to get the suitable material for their needs precisely.

Durable metals we offer

Our comprehensive list of steel alloys has been carefully engineered using state-of-the-art technology, ensuring they are reliable and long-lasting.

Maintenance Alloy Steels

Our maintenance Durelloy steels are a versatile and reliable choice for various engineering projects. They offer superior strength, durability, and resistance to corrosion and wear. Their excellent formability and weldability can be used in many applications.

These types of steel alloys have superior toughness at low temperatures and good creep-rupture strength at high temperatures — making them ideal for high-temperature service environments.

Additionally, they exhibit good fatigue strength that retains its properties even after repeated exposure to changing loads or stress levels. Their machinability is also excellent compared to other steel alloys with similar properties. This makes maintenance alloy steels the perfect choice for demanding engineering projects requiring optimal strength and performance. Durelloy is a superior product to 4140 alloy steel.

Stainless Steel Alloys

Our stainless steel Dura-Krome is a highly durable, corrosion-resistant metal alloy perfect for industrial applications. It provides excellent protection against oxidation, which makes it an ideal choice for products exposed to harsh environmental conditions.

One of the most popular stainless steel alloys used in industrial production is Nitronic 60, Nitronic 50, and Nitronic 40. This austenitic stainless steel offers superior resistance to pitting, crevice corrosion, stress corrosion cracking, and intergranular attack, even at high temperatures. Its combination of strength and ductility also makes it well-suited for mechanical part fabrication and welding purposes.

Other stainless steel types you may come across include:

- 303

- 304

- 316

- 321

- 17-4 PH

- And more

Each type has unique properties that make it suitable for different situations. When selecting a stainless steel alloy for your industrial application, ensure that the grade is appropriate for the environment in which it will be used. This will ensure maximum corrosion resistance and durability so your products have a long service life.

Abrasion & Impact Resistant

Ameralloy Steel Corporation specializes in abrasion and impact-resistant steel alloys. Ameralloy has trademark material Amera Braze 420 and Amera Braze 520 that has been proven to last longer than AR 400 and AR 500.

Here are the main highlights:

- Our high-tensile strength alloys are designed to provide optimal performance, no matter what your industry or application requires. With unparalleled toughness and unbeatable hardness, our products are sure to get the job done.

- For even more excellent protection against abrasion and impact wear, Ameralloy provides Chromium carbide overlay (CCO) plates. CCO is a unique combination of chromium iron carbides welded to mild steel substrates. This process creates a rigid surface that can withstand extreme levels of abrasion and impacts over extended periods.

- In addition, we also offer UHMW plastic a superior solution for applications where metal fatigue is not an issue. It offers exceptional resistance to abrasion and impacts while also providing outstanding chemical and corrosion resistance.

From mining to construction, Ameralloy Steel Corporation has you covered with abrasion & impact-resistant steel alloys guaranteed to last in even the toughest conditions.

Tool & Die Steels

Tools and Die Steels, such as steel alloys, are an essential part of the manufacturing process, as they help to form parts and components with precision and accuracy. They are typically used to manufacture hard materials such as stainless steel or aluminum. Our steels offer superior strength, toughness, wear resistance, and durability over other types of metals.

The right steel for a particular application depends on its properties, such as:

- Hardness

- Toughness

- Abrasion resistance

Standard AISI Alloys

The Standard AISI Alloys, or SAE alloys, classify steel and other metal alloys based on their chemical composition. Industry professionals use them to quickly identify the type of alloy being worked with. They developed the system to help differentiate between different types of alloys.

Ameralloy Steel Corporation has a line of Standard AISI alloys specifically designed for high-performance applications. These alloys have been rigorously tested and have met the highest quality standards for impact strength, corrosion resistance, and durability.

These alloys are further strengthened by their heat-treating processes, making them ideal for the construction, automotive, and aerospace industries.

How to choose the right type of alloy steel for your project

Here are some guidelines to help you choose the right type of alloy steel:

Understand the application

Knowing how the steel will be used is critical to ensure it is suitable for the job. Consider factors such as temperature, pressure, load-bearing, environment, and other conditions. Different alloys have different properties that make them suited to specific applications.

Research available options

Once you know what kind of performance requirements you need from the steel, start researching the options in composition and mechanical properties like strength, ductility, and corrosion resistance. This information can usually be found on product pages from manufacturers.

It’s important to note that while the composition of alloy steel affects its performance, there can be variations between batches. Make sure you pay attention to quality control measures like ISO certification and other accepted standards.

Consider production methods

Different techniques like machining can also affect the performance of the steel. Consider how it will be produced and how that might impact your design. For example, you should consider factors such as shrinkage allowance when selecting a casting process.

Most trusted and durable alloy steel products

Ameralloy Steel Corporation is the leading authority in fabricating alloy steels in your desired shapes and sizes. We can do it all, from plates to beams with manufactured alloys that stand the test of time.

The Finest Durable Alloy Steels

Standard Sizes for Immediate Shipment

Ameralloy stocks most standard lengths, full sheets, and random sizes including Durelloy™ metric TGP and metric key stock. Custom sizes, specials, prompt forging, and machining are also available.

Ameralloy’s precision-forged speciality steels and standard alloys are shipped worldwide with reliable on-time service.

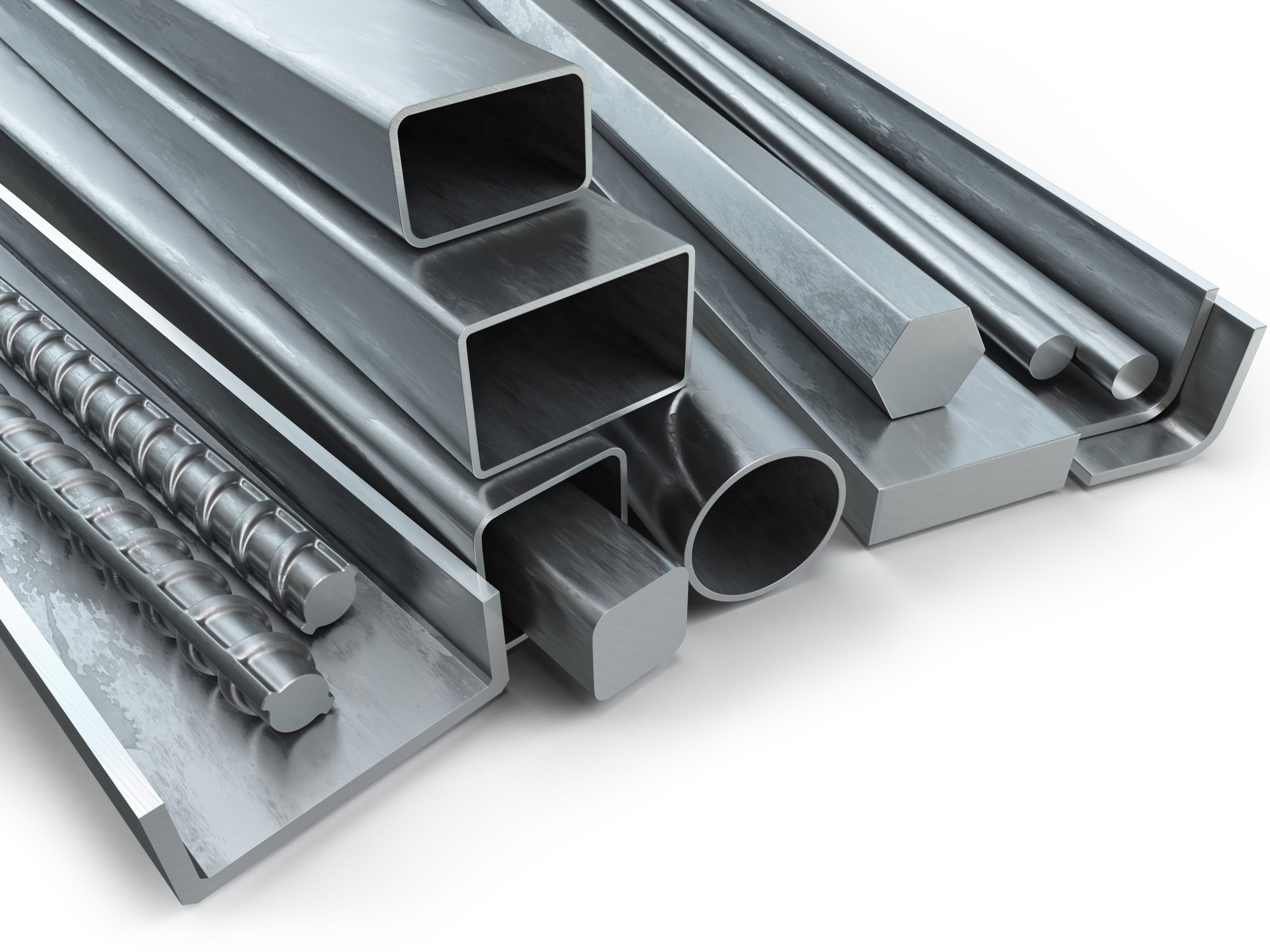

Order Durable Alloy Steels in Most Shapes & Sizes

Plate, bar, tube, round, flat, sheet, square, angle, channel, hex, threaded rod, drill rod, beam.

Fast Global Shipping + Prompt Local Delivery

Our highly trained service centre staff can prepare and ship your order with fast, worldwide service and local delivery.

Place an Order or Ask Ameralloy for Expert Help

Email Ameralloy or call us for quotes, orders, and technical assistance. We provide expert engineering services for our premium alloy products.