Nickel Alloy Products Supplier

There are many advantages to working with nickel alloys, including better corrosion resistance, strength, and heat resistance. In the Nickel Alloy industry, Ameralloy Steel is a trusted source.

A comparison of nickel and stainless steel

There are numerous applications for Nickel Alloy Heat Exchangers, commonly used to manage and eliminate heat. Their corrosion resistance is superior when there is excess alkali in the environment.

Nickel Alloy

Nickel alloy is a non-ferrous metal with high strength and toughness, corrosion resistance, and superior high-temperature qualities. The electrical, magnetic, and magneto strictive properties of commercially pure nickel are excellent. We can offer a wide range of bar, plate, sheet, pipe, tube, coil, and customer profiles.

Alloys we offer:

Nickel 200/201, contains at least 99.6 percent nickel, which is known as commercial purity. One of the materials known for keeping purity, 201, is the low-carbon variant of Nickel 200, which has excellent resistance to solvents and corrosive substances.

Nickel 400 – 405 solid solution alloy. This nickel-based alloy is utilized in various industries, including maritime and chemical processing. Cold rolling is the most common way to harden and strengthen.

600/601

Nickel 600 has a nickel content of 72% and is commonly used in applications requiring corrosion and heat resistance. This is a terrific combination of being easy to work with and exceptionally durable and rugged.

By default, nickel 625 contains 58 percent nickel, and chromium accounts for more than 20 percent of the overall weight. Cryogenic and 1800-degree temperatures are no match for this metal’s ability to endure corrosion and fabricate well.

To be considered Nickel 718, it must contain at least 50%. Known for its resistance to post-weld cracking, 718 is an excellent choice.

Nickel 800H is also known as a nickel alloy. By default, nickel 800H consists of only 30 to 35 percent nickel and is an amalgamation of chromium and iron, with a minimum composition of 39.5 percent. Originally intended to combine the advantages of all the metals stated, this ensures high-temperature strength, chemical property maintenance, oxidation resistance, high temperatures, and high-temperature corrosion.

There must be at least 38 percent nickel and at least 80% chromium in Nickel 825, which has a minimum of 22% chrome. Stress corrosion cracking-resistant alloy has been developed for this application.

Only 12.5% of the nickel in Nickel 901 is chromium, and the remaining 42.5 percent is nickel, with iron acting as a stabilizer. Because of the variation in iron levels, it’s not a good idea to rely too much on iron as a determining factor.

K500

Nickel K500 is corrosion-resistant steel with a minimum nickel content of 63 percent. Because the base adds aluminum and titanium, it can withstand high temperatures.

L605

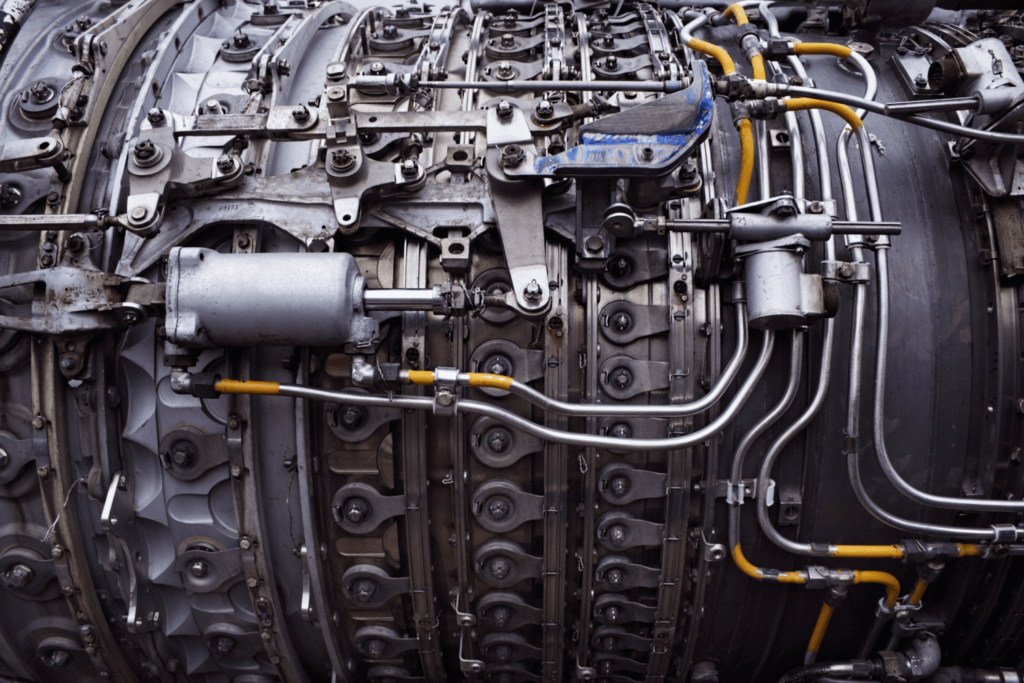

Nickel L605 is a mixed metal with a minimum nickel content of 9%, a minimum tungsten content of 14%, and a minimum chrome content of 19%. The outstanding high-temperature strength of this alloy allows it to withstand temperatures of up to 2,000 degrees. When it comes to gas turbines, this is the best material to use on things like rings, blades, and combustion chambers.

Alloy C276

Chromium, molybdenum, iron, tungsten, and nickel make up the bulk of the material. Low carbon content reduces precipitation during welding while increasing resistance to localized corrosion.

Alloy X-750

Nickel makes up at least 70% of Alloy X-750’s composition, with chromium and iron rounding out the top three.

Alloy A286

As a result, Alloy A286 has excellent oxidation resistance and strength and a temperature range of up to 1300 degrees Fahrenheit. When combined with nickel, chromium, and titanium, it is a highly versatile metal.

Alloy 188

Another chromium-nickel-tungsten alloy, Alloy 188, can withstand temperatures up to 2,000 degrees Fahrenheit and remains unbreakable even under such grueling conditions.

Not sure what you are looking for? Contact Ameralloy Steel an ISO 9001 certified supplier that specializes in finding hard-to-find Stainless and Alloys. Along with our proprietary grades Amera-Braze, Durelloy, and Dura-Krome. Our knowledgeable sales team will help you find what you are looking for. With many shapes, sizes, and material grades available, we can help you find what you are looking for. The most common items stocked are Tube, Pipe, Sheet, Plate, Hex bar, Square bar, Round bar, Threaded bar, Pump Shaft, and Millimeter sizes. We offer added fabrication services. Contact us now for the current price and delivery.