Color Code:

Color Code: ORANGE WITH BLACK STRIPE

Ameralloy High Speed-2 is the most widely used type of high-speed steel. It is generally used for the same applications as T-1 high speed. Ameralloy High Speed-2 has higher carbon content and balanced analysis producing properties applicable to all general-purpose high speed uses.

Typical Analysis

- Carbon .86

- Chromium 4.15

- Tungsten 6.35

- Molybdenum 5.00

- Vanadium 1.90

Applications

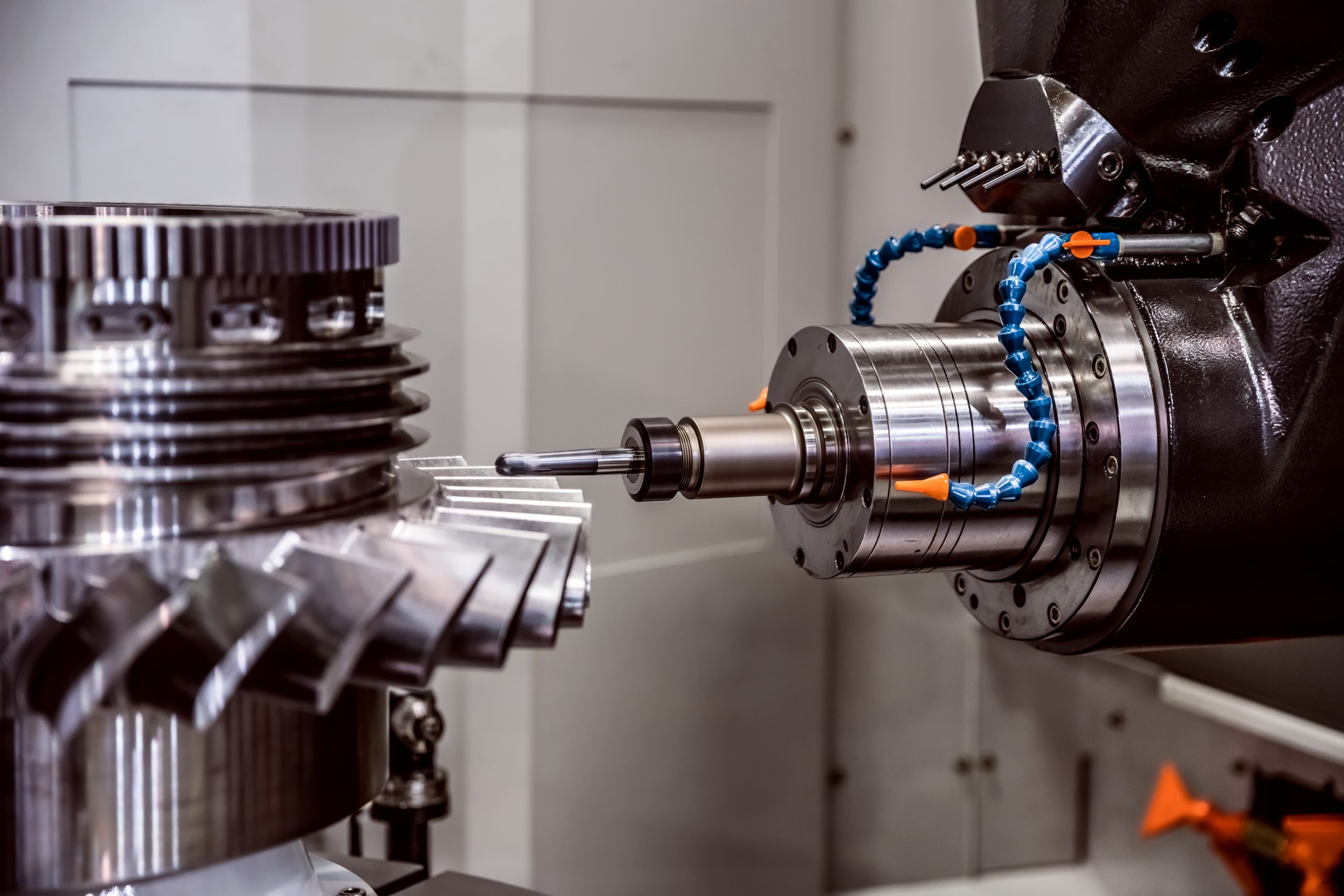

- Lathe tools

- Planer tools

- Drills

- Taps

- Reamers

- Broachers

- Milling cutters

- Form cutters

- Wood knives

- Gear cutters

- End mills

Features And Advantages

- Balanced abrasion and shock resistance

- Good red-hardness

- Weighs 6% less than T-1 high speed

- Can be hardened at 100° below T-1 high speed

Characteristics

Machinability Like all highly alloyed steels, High Speed-2 machines with somewhat more difficulty than the lower alloyed steels. It is rated at 65 as compared to a 1% carbon tool steel, which is rated at 100.

Critical points Critical points obtained by dilatometer tests when heating at a rate of 400° per hour and cooling at 30° per hour are as follows:

Heating – Ac range 1530° to 1610°F

Cooling – Ar range 1430° to 1380°F

Heat Treatment

Forging 2050°–2100°F, stop at 1800°F and cool slowly

Annealing 1600°F, cool slowly. Brinell 241 max.

Preheating 1550°F, soak before hardening

Hardening 2250° to 2275°F, oil-quench

Tempering 1000°–1050°F, Rockwell C 65-66

Available Shapes And Sizes

- Rounds

- Squares

- Flats

Standard lengths 10’–12’ or cut to specified length. Modified and special sizes available upon request. Prompt forging service available.

Rounds Decarb Free

| 1/16 5/64 3/32 7/64 1/8 9/64 5/32 11/64 3/16 13/64 7/32 15/64 1/4 17/64 9/32 5/16 21/64 11/32 3/8 25/64 13/32 7/16 15/32 1/2 17/32 9/16 |

5/8 21/32 11/16 3/4 5/32 13/16 7/8 15/16 31/32 1 1.015 1.055 1-1 /16 1-1/8 1.160 1-3/16 1.192 1-7 /32 1-1/4 1.275 1-5/16 1.360 1-3/8 1-7 /16 1.450 1-1/2 |

1.515 1-9/16 1-19/32 1.610 1-5/8 1.650 1-11/16 1.700 1-3/4 1.765 1-49/64 1-25/32 1-13/16 1.860 1-7/8 1.890 1-15/16 1-31/32 2 2.015 2-1/64 2-1/32 2-1/16 2-1/8 2-3/16 2-1/4 |

2-17/64 2-5/16 2-3/8 2-7/16 2-1/2 2-17/32 2.515 2-9/16 2.610 2-5/8 2-11 /16 2-3/4 2-13/16 2-7/8 2-15/16 3 3.015 3-1 /16 3-1/8 3-1/4 3-5/16 3-3/8 3-7/16 3-1/2 3-9/16 3-5/8 |

3-11 /16 3-3/4 3-13/16 3-7/8 3-15/16 4 4-1/32 4-1/16 4-1/8 4-1/4 4-3/8 4-1/2 4-5/8 4-3/4 4-25/32 4-7/8 5 5-1/4 5-1/2 5-3/4 6 6-1/4 6-1/2 7 7-1/2 8 |

Flats and Squares Decarb Free plus .015/ .030

| 1/4 | 1/2 | 5/8 | 3/4 | 7/8 |

|---|---|---|---|---|

| x 1/4 x 1 x 1-1/2 3/8 x 3/8 x 1 x 1-1 /4 x 1-1 /2 x 2 x 3 |

x 1/2 x 3/4 x 1 x 1-1/2 x 2 x 2-1/2 x 3 x 4 x 6 x 8 x 10 x 12 |

x 5/8 x 1-1 /4 x 1-1 /2 x 2 x 2-1/4 |

x 3/4 x 1 x 1-1 /2 x 2 x 2-1/2 x 3 x 4 x 5 x 6 x 8 x 10 x 12 |

x 1-1/2 x 1-3/4 x 2 x 3 x 4 x 5 x 6 x 8 x 10 x 12 |

| 1 | 1-1/4 | 1-1/2 | 1-3/4 | 2 |

| x 1 x 1-1 /4 x 1-1 /2 x 2 x 2-1/2 x 3 x 4 x 5 x 6 x 8 x 10 x 12 |

x-1 /4 x 1-1 /2 x 2 x 2-1/2 x 3 x 4 x 5 x 6 x 8 x 10 x 12 |

x 1-1/2 x 2 x 2-1/2 x 3 x 4 x 6 x 8 x 10 x 12 |

x 1-3/4 x 2 x 2-1/2 x 3 x 4 x 5 x 6 x 8 x 10 x 12 |

x 2 x 2-1/2 x 3 x 3-1/2 x 4 x 5 x 6 x 8 x 10 x 12 |

| 2-1/2 | 3 | |||

| x 2-12 x 3 x 4 x 6 x 8 x 10 x 12 |

x 3 x 4 x 6 x 8 x 10 x 12 |

|||

Not sure what you are looking for? Contact Ameralloy Steel an ISO 9001 certified supplier that specializes in finding hard-to-find Stainless and Alloys. Along with our proprietary grades Amera-Braze, Durelloy, and Dura-Krome. Our knowledgeable sales team will help you find what you are looking for. With many shapes, sizes, and material grades available, we can help you find what you are looking for. The most common items stocked are Tube, Pipe, Sheet, Plate, Hex bar, Square bar, Round bar, Threaded bar, Pump Shaft, and Millimeter sizes. We offer added fabrication services. Contact us now for the current price and delivery.