Color Code:

Color Code: BLUE

Double-C Chromium Carbide Overlay is the perfect solution to premature equipment and part wear in extremely abrasive conditions with low to moderate impact.

Double-C was engineered utilizing an innovative new cladding process to create the most wear-resistant surface available.

Double-C’s low carbon steel base allows for weldments, bolts, and stud attachments. The alloy overlays provide a surface with superior wear resistance. Double-C reduces your maintenance costs and virtually eliminates unnecessary downtime. Double-C has proven durability and value through punishing use in the mining industry, coke, cement, and asphalt plants, power utilities, and pulp & paper mills.

Typical Analysis

- Carbon 4.8

- Silicon .50

- Chromium 26.8

- Manganese 2.0

Available Sizes

| Standard Thickness | Cladding Overlay | A-36 Base Plate |

|---|---|---|

| 3/8” | 1/8” | 1/4” |

| 1/2” | 1/4” | 1/4” |

| 5/8” | 1/4” | 3/8” |

| 3/4” | 3/8” | 3/8” |

| 7/8” | 3/8” | 1/2” |

| 1” | 1/2” | 1/2” |

Double-C ®CHROMIUM CARBIDE OVERLAY

fabrication

General Characteristics

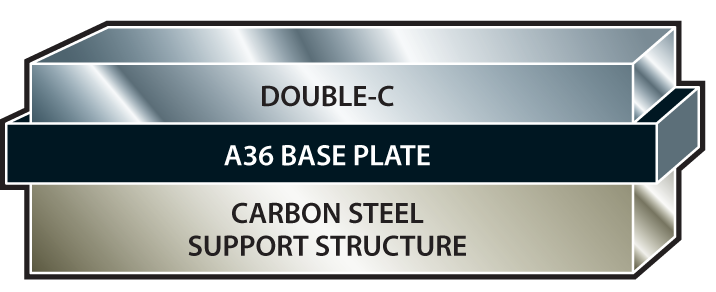

Double-C is a fusion-clad chromium carbide composite overlay that has been permanently bonded to a carbon steel base. Double-C carries a hardness rating of Rockwell C 60–62. Characterized by a high chromium and high carbon content, this material is more resistant to wear, corrosion, and heat.

- Base plate ASTM A36 is used to enhance Double-C weldability and ductility.

- Appearance Double-C overlay is applied in 1” to 1-1/4” beads on the base metal, giving the product a ribbed appearance. The cladding process produces natural stress relief cracks, providing maximum wear life in heavily abrasive applications by relieving stresses in the plate. The stress relief cracks are limited to the overlay and do not extend to the base plate. Double overlay is recommended for severe wear applications.

- Heat resistance Double-C is effective up to 1250°F with an abrasion ratio of 20:1 over heat resistant steels. Repeated heating and cooling does not affect its wear-resistant properties.

- Impact resistance The mild steel base metal absorbs shock, providing moderate resistance to impact-type wear. The impact resistance of Double-C improves with the thickness of the base metal.

Fabrication Instructions

Using proper fabrication methods, the mild steel base and arc-welded overlay bends readily. Double-C can be specially rolled and formed to your specifications at our plant.

- Cutting Use plasma burning equipment, air arc, or abrasive saws when cutting, piercing, or beveling Double-C. Best results are obtained when cutting from the low carbon steel side.

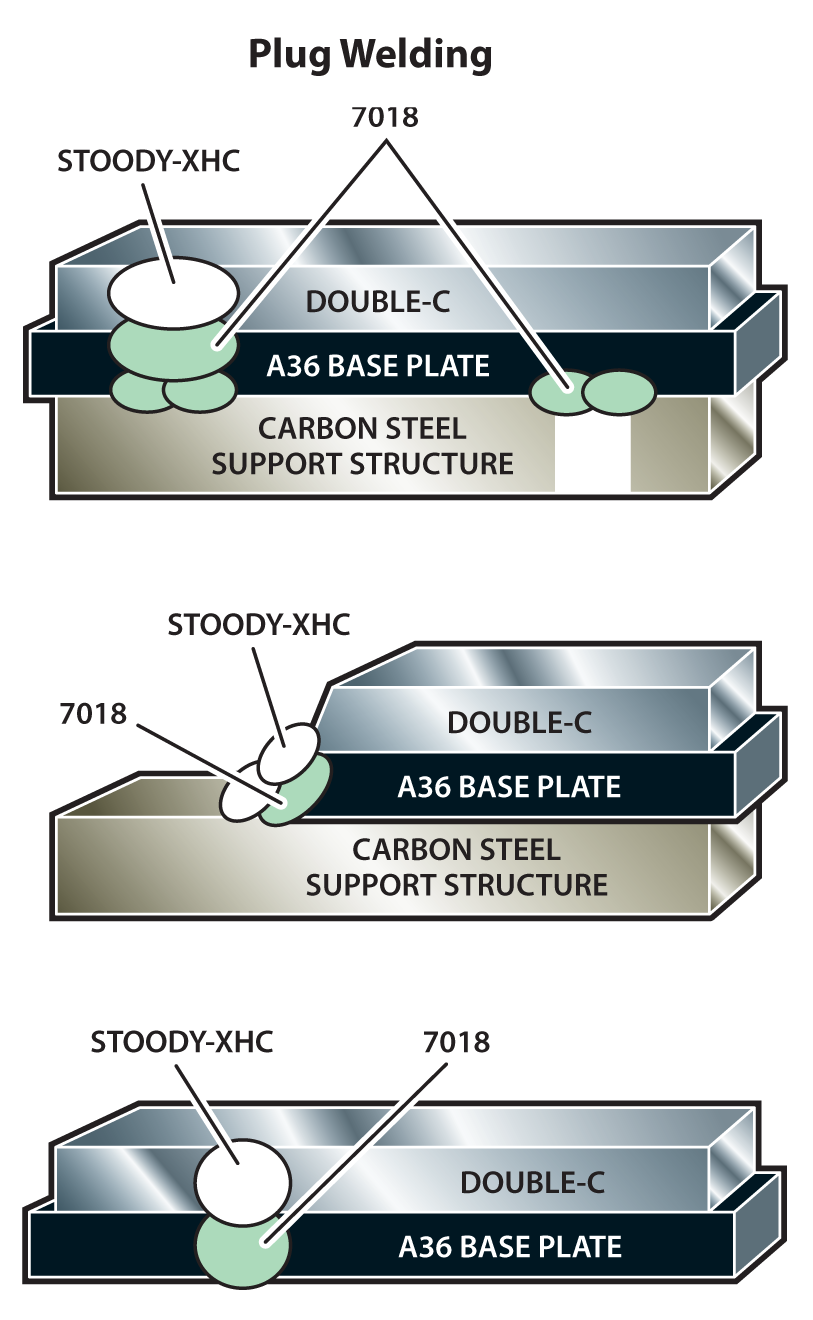

- Welding When welding Double-C into position, it is recommended that the weld extend thicker than the mild steel base plate. The life of the weld joint can be enhanced by running a bead of hard surface along the welded area. These precautions will prevent wearing of the mild steel base plate as well as overlay chipping.

Not sure what you are looking for? Contact Ameralloy Steel an ISO 9001 certified supplier that specializes in finding hard-to-find Stainless and Alloys. Along with our proprietary grades Amera-Braze, Durelloy, and Dura-Krome. Our knowledgeable sales team will help you find what you are looking for. With many shapes, sizes, and material grades available, we can help you find what you are looking for. The most common items stocked are Tube, Pipe, Sheet, Plate, Hex bar, Square bar, Round bar, Threaded bar, Pump Shaft, and Millimeter sizes. We offer added fabrication services. Contact us now for the current price and delivery.