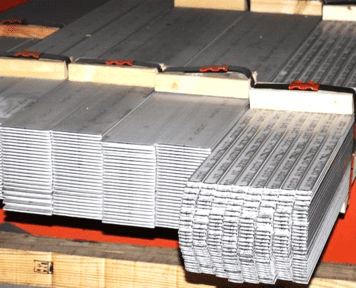

Stainless Steel Flat Bar

There are many different grades of stainless steel flat bars available. However, stainless steel 304/304L and 316/316L flat bars are among our most often requested products. Stainless steel flat bar is available in Sheared and True Milled.

The dimensional tolerance distinguishes between a True mill flat bar and a flat bar cut from a plate. For the best finish, the True Mill flat bar has tighter tolerances for width and thickness. Sheard or cut from a plate has a larger diametrical tolerance. The flat bar cut from plate has a HARP finish. Plate thickness tolerance for plate thicknesses ranges from 0.010″ to 0.090″ and increases with consistency, while the minimum under-tolerance is 0.010″.

Stainless Steel Flat Bar

- Hot-rolled – Stainless flat bars are available in hot-rolled form. Temperatures of 1325-1500 degrees Celsius are required to form stainless steel. This is above the point at which steel begins to solidify. The material at this temperature can be formed, and mills can mass produce it to our exact specifications.

- Sheared flat bar – We can provide Sheared bar from the plate. Just let us know if you have a specific length in mind, and we’ll do our best to accommodate. Tolerances in width will be greater if one edge has a slightly rounded radius. The hot-rolled finish will not be uniform on all sides of the material. The cut side of the material can differ. The steel plate can be turned into a flat bar to fulfill ASTM A276, and A479 is allowed via ASTM A484. If you’re interested in a custom finish, grits up to 180 are available upon request.

- True Mill – Has tighter tolerance and in most cases, has cold finish. Adding True Mill and cold rolling to the hot rolling process is a different stage. Cold rolled produces a superior product, but the process is much more time-consuming than hot rolled. Cold rolled is sent to cooling plants where it is annealed or temper rolled. As the material is compressed into smaller and smaller pieces, it will not lose any of its density. Material can endure the same or even more concentrated force while taking up a concentration of energy.

Plates and Sheets vs. Flat Bars: The Difference

The line shows material thickness. Generally, stainless steel plates are slightly thicker than stainless steel sheets. Because we frequently request sheet metal that should be a plate, here is an explanation.

- Stainless Steel Sheet – .018″-.250″ is the thinnest thickness of sheet obtainable. This item is available in various lengths and widths. The most common way to order a stainless sheet is by the gauge, which refers to how thick, comprehensive, and long a piece is.

- Stainless Steel Plate – Plates may have a #1 HRAP finish if they are 3/16′′ to 6′′ thick or thicker. The scale is 48″ wide and can be as long as 30 feet. We can make any size you need.

- Stainless Steel Bars – It is common for stainless steel bar stock to be produced in various grain patterns, but it is not as comprehensive as stainless steel plates and sheets. The bar’s breadth or length determines whether it is a plate or bar.

- True mill flat bar – Tolerances for width and thickness are restrictive with true mill flat bar, which has sharper edges. A smoother finish and fewer twists will be achieved on all four sides.

- Sheared flat bar – We can provide Sheared bar from the plate. Just let us know if you have a specific length in mind, and we’ll do our best to accommodate. Tolerances in width will be greater if one edge has a slightly rounded radius. The hot-rolled finish will not be uniform on all sides of the material. The cut side of the material can differ. The steel plate can be turned into a flat bar to fulfill ASTM A276, and A479 is allowed via ASTM A484. If you’re interested in a custom finish, grits up to 180 are available upon request.

- Cold Drawn Flat Bar – 303 Stainless Steel Cold Drawn Flat Bars are offered. You can get additional details on width, thickness, and limits by contacting us right away.

Several alloys have flat or square bar production limits because of the need for aerospace applications or the inability to be cut from the plate. Titanium alloys and PH15-5 are examples of grades that cannot be cut because of cross grain.

Not sure what you are looking for? Contact Ameralloy Steel an ISO 9001 certified supplier that specializes in finding hard-to-find Stainless and Alloys. Along with our proprietary grades Amera-Braze, Durelloy, and Dura-Krome. Our knowledgeable sales team will help you find what you are looking for. With many shapes, sizes, and material grades available, we can help you find what you are looking for. The most common items stocked are Tube, Pipe, Sheet, Plate, Hex bar, Square bar, Round bar, Threaded bar, Pump Shaft, and Millimeter sizes. We offer added fabrication services. Contact us now for the current price and delivery.