Ameralloy Steel Corporation has a full range of fabrication services designed for numerous industries to support their multiple applications. These fabrication capabilities include waterjet cutting, plasma cutting, flame cutting, laser cutting, and saw cutting, all metal cutting services. Our team of experienced engineers can advise you on the best service according to your needs.

You will experience excellent results of the highest quality standards. Using machines equipped with the latest technology to achieve accurate and consistent results for your fabrication. We can also offer hole drilling, taping, and countersinking.

Fabrication Capabilities & Services

We are the most reputable metal cutting service used for various applications, operations, and projects. Our goal is to deliver customer satisfaction, and we can reach that through our top-notch fabrication capabilities.

Can offer trademark material that will outperform standard alloys. Below are some of our most popular and sought-after grades. Not sure what you are looking for, contact us now.

Laser Cutting

Our laser cutting service uses a laser to cut the material into our client’s desired shape. We use a CNC or computer numerical control to direct the laser beam to the material. The result is a product with a high-quality surface finish edge that minimizes additional machining needed.

Benefits of laser cutting machines:

- Produces precise cuts

- It can cut through different types of steel products

- It can handle high-production runs

- Minimal Heat affected surface area

- Precision cut edges

Plasma Cutting

Our plasma cutting service is also a melting process where ionized gas is used to melt or expel material from the cut. Here, an electric arc is hit on an electrode and the workpiece. The plasma jet is formed when the electrode is submerged in a water or air-cooled gas nozzle. Benefits to using plasma cutting etching and beveling can be performed when cutting.

Industries that use plasma cutting:

- Automotive

- Industrial

- Fabrication shops

- Construction

WaterJet Cutting

Our waterjet cutting services involve high-pressure jets used to cut steel, metal, and other materials. We provide an efficient cutting process that can produce intricate shapes even with thick materials. A small precision nozzle is where the water will run through by the pressurized pumps. When using a water jet, there are no hear affected areas.

Uses of waterjet cutting:

- Aerospace: The aerospace industry requires complex but accurate precision components. Therefore, making water jet cutting is integral to aerospace production due to its minimal error results.

- Auto: Water jet cutting can be integrated into the robotic systems of an automobile. Plus, it doesn’t have heat-affected zones, which means the workpiece has smooth, burr-free surfaces.

- Electronics: Water jet cutting is very cost-effective, so it has become critical to creating electronic parts and components.

Flame Cutting

Flame cutting is a metal cutting service, which is also called oxy fuel cutting, when the material is cut by raising the temperature to ignition temperature through an oxy-fuel gas flame. It’s primarily used to shape and separate various steel components. It is one of the most economical ways to cut metal.

Benefits of flame cutting:

- Can be portable no power needed

- Used to cut thick sections

- Can cut round, square, and rectangle shapes

- Used out in the field

The following are our thickness range specifications for our flame cutting service:

- Thickness range: ¼” thick up to 14” thick

- Maximum table cutting capacity: Up to 120” x 600”

- Overall tolerance by thickness: Less than 2” thick = 1/8”, 2″ to <4″ = 3/16″, 4″ to <8″ = 1/4″, 8″ to <10″ = 5/16″, 10″ to <12″ = 1/2″

- Minimum hole size is equal to the thickness of the plate

- Materials: Carbon

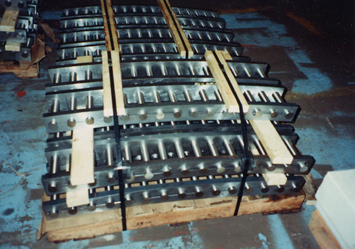

Saw Cutting

Saw cutting or sawing is one of the most popular metal cutting services available today. Ideal for cutting metal off all grades for making blanks. We offer bar sawing, miter sawing, and structural sawing, depending on your needs. We can offer one piece cuts or thousand with our automated cutting solutions.

Choose Ameralloy Steel Corporation’s Different Fabrication Services

Our fabrication capabilities and metal cutting services allow us to meet our client’s expectations by determining the best method for their projects. You can choose from the above techniques, and we can do the rest. By having on staff CAD designers you can have your project done right the first time.

Contact us today and see what we can do for you. We are confident we can help you get the desired results with our quick turnarounds. Plus, you may also request a quote, and we can give you an estimate of your projects.

Not sure what you are looking for? contact Ameralloy Steel an ISO 9001 certified supplier who specializes in finding hard-to-find Stainless and Alloys. Along with our proprietary grades Amera-Braze, Durelloy, and Dura-Krome. Our knowledgeable sales team will help you find what you are looking for. With many shapes, sizes, and material grades available, we can help you find what you are looking for. The most common items stocked are Tube, Pipe, Sheet, Plate, Hex bar, Square bar, Round bar, Threaded bar, Pump Shaft, and Millimeter sizes. We can also offer added fabrication services. Contact us now for the current price and delivery.