Stainless Steel Beams Supplier

Ameralloy Steel maintains a large inventory as a stainless-steel beams distributor. 304/304L, 316/316L and duplex beams are among the many grades and varieties we keep in stock.

All our beams are made to meet ASTM 276, A484, and A479/A479M requirements and are available for purchase. For many industries, stainless steel beams are an essential component. Extruded, hot-rolled, or laser-fused stainless-steel beams are all options. Many industries and applications benefit from stainless steel channels because of the qualities and advantages listed below.

- Structural integrity and toughness

- Resistant to Oxidation

- Use in hygienic and corrosive conditions

Steel Beam Specifications and Dimensions

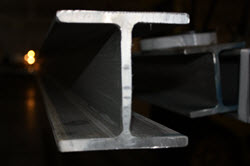

Because of their unique design, stainless steel beams come in many sizes. Stainless plates are welded on top of a supporting center to create the beams. That allows movement and stability, especially in the case of moving stress.

• Web:

Beam webs are graded by thickness, and the web is the beam’s core. The connecting steel ensures the integrity of the beams. It serves to distribute pressure by joining the two flanges together.

• Flange:

The flange’s top and bottom stainless plates bearing the load’s weight. Flattened flanges distribute pressure evenly. In I-Beams case, the two parts are run parallel.

There are a variety of stainless-steel beam options to choose from

Most common types of stainless-steel beams we provide:

- 304/304L

- 316/316L

- 2205 Duplex

Because of their shape, stainless steel beams are known as “I” Beams. The other beams are called in comparison to the I-beam, the universal and most recognized form.

• I Beam

The I Beam are some of the most often used beams. There are a wide variety of sizes available that can be offered. The I-Beam is made of the web and flange. The web is usually higher or taller than the flanges, making it look like the capital letter I. Some stainless I beams are rolled and have a tapered inside radius near the web.

• H Beam

Although the H-beam is more durable than the I-beam, it is also more labour-intensive to manufacture. Three separate components are welded together to form an H-Beam rather than rolled into one piece. Because you’re utilizing the milling equipment three times to reinforce material instead of using the equipment once to manufacture a single thing, each section is substantially stronger. Regarding overall weight and pressure capacity, the H-Beam is far superior to the I-Beam.

• W Beam

Wide flanges on the W-beam, as opposed to tapered flanges, aid in weight distribution. Because of the large flange, the same material is used throughout. The ‘Wide-Flange’ beam is also known as the ‘W Beam’.

• S Beam

The ‘American Standard Beams’ are another name for the S Beam. I-beams are a close relative of these. S-beams are synonymous with the “American Standard” I-beam, as opposed to a different I-beam standard used in other countries. Because I-beam is a widely discussed beam with varied dimensions in different countries, this standard was developed.

Ameralloy Steel goal to provide the best products and the most dependable honest service. We’ve been family-owned for over 40 plus years. Contact us now with any questions about your next project.

Not sure what you are looking for? Contact Ameralloy Steel an ISO 9001 certified supplier that specializes in finding hard-to-find Stainless and Alloys. Along with our proprietary grades Amera-Braze, Durelloy, and Dura-Krome. Our knowledgeable sales team will help you find what you are looking for. With many shapes, sizes, and material grades available, we can help you find what you are looking for. The most common items stocked are Tube, Pipe, Sheet, Plate, Hex bar, Square bar, Round bar, Threaded bar, Pump Shaft, and Millimeter sizes. We offer added fabrication services. Contact us now for the current price and delivery.